| Availability: | |

|---|---|

| Quantity: | |

SinoCleansky LNG microbulk station is a smart and modular design for small LNG applications.

The whole LNG station is built on skid, with LNG storage, regasification, pressure regulation, measurement, odorization and etc, which is very convenient for installation and operation.

Typical models are 7.2m3, 16bar working pressure, with 2 sets 100Nm3/H vaporizer, etc. Customization is available upon your specific requirements.

The 7200L LNG Microbulk Tank from SinoCleansky is a compact, all-in-one solution for small-scale LNG storage and regasification—perfect for small industrial facilities, restaurants, and remote communities.

Gross volume of 7,215 liters

Gas delivery rate of 200 Nm³/H

Combines storage, vaporization, pressure regulation, metering, and odorization into a ONE skid-mounted unit

High vacuum multi-layer insulation minimizes heat ingress, reducing boil-off loss to <0.5% per day

Built to ASME VIII Section 1 standards

Use SA-240M 304 stainless steel for both inner and outer vessels, ensuring durability and corrosion resistance.

As a one-stop NGV/CNG/LNG provider, we tailor the unit to client needs—from adjusting vaporizer capacity to adding remote monitoring systems—making it a flexible solution for decentralized gas supply.

Model No.: LMS7200-100

Gross Volume: 7215 L (usable volume: 6800 L)

Height: 3372 mm

Diameter: 2212 mm (compact design for narrow installation spaces)

Gas Delivery Rate: 200 NM³/H (via 2 sets of 100 NM³/H ambient vaporizers)

Working Pressure: 1.6 MPa (design pressure: 2.0 MPa)

Design Temperature: -196℃ to 50℃

Medium: LNG (compatible with LNG with methane content ≥95%)

Insulation: High vacuum multi-layer insulation (vacuum degree ≤ 1×10⁻³ Pa·L/s)

Key Components: Fisher brand pressure regulators (double-route for redundancy), SS Chinese brand ball valves, pressure-differential odorizer (outlet pressure: 1.5 bar).

| Item | Parameters | |

LMS7200-100 | ||

Gross Volume | 7,215 L | |

Loading Medium | LNG | |

Design Code | ASME Ⅷ Sec.1 | |

Main Material | Inner Vessel | SA-240M 304 |

Outer Vessel | SA-240M 304 | |

Design Temperature | ‐196~50℃ | |

Working Pressure | 1.6 Mpa | |

Isolating Type | High vacuum Multi-layer | |

Vaporizing skid | 100NM3/H x 2 ambient vaporizers (one work & one stand-by); | |

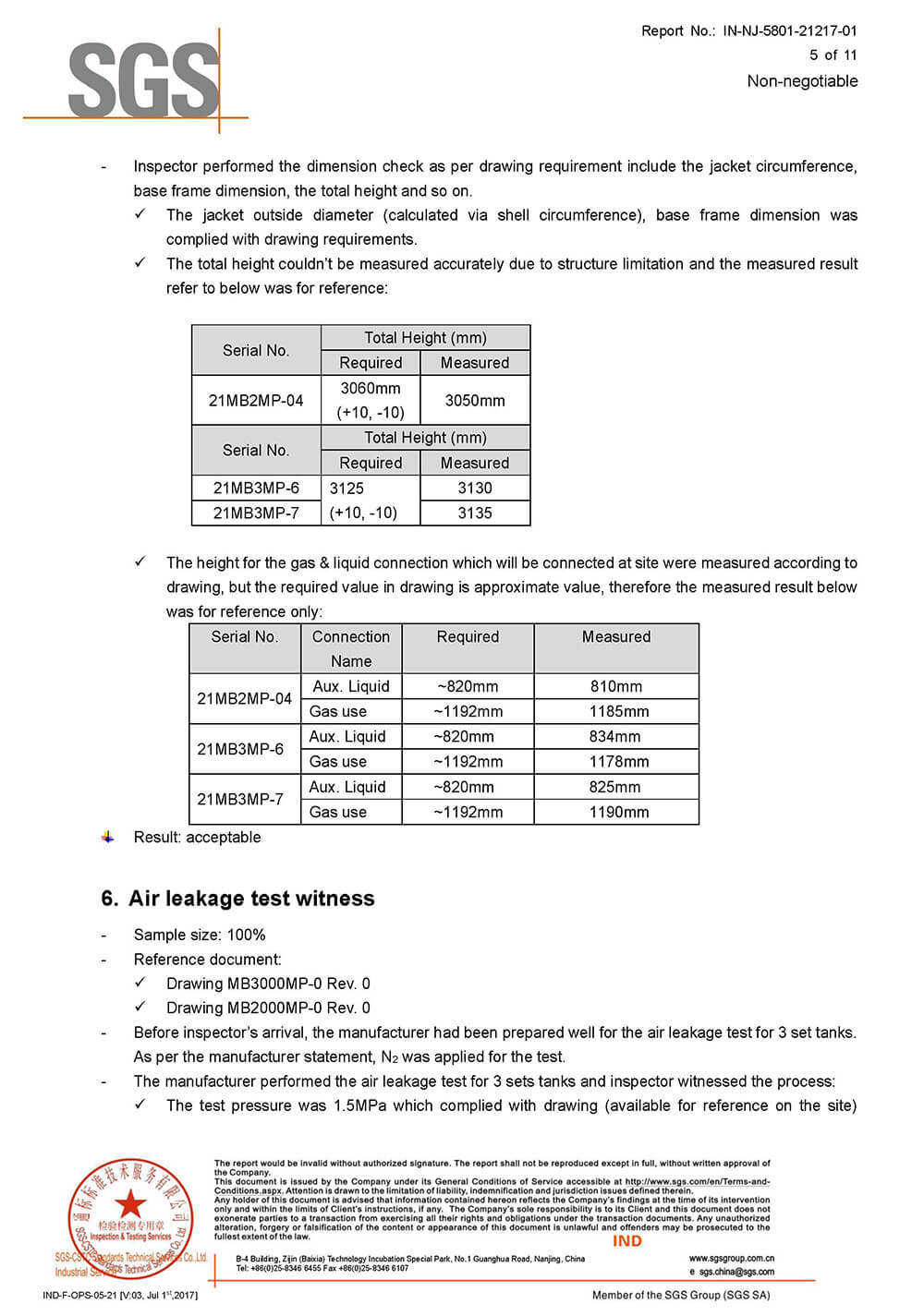

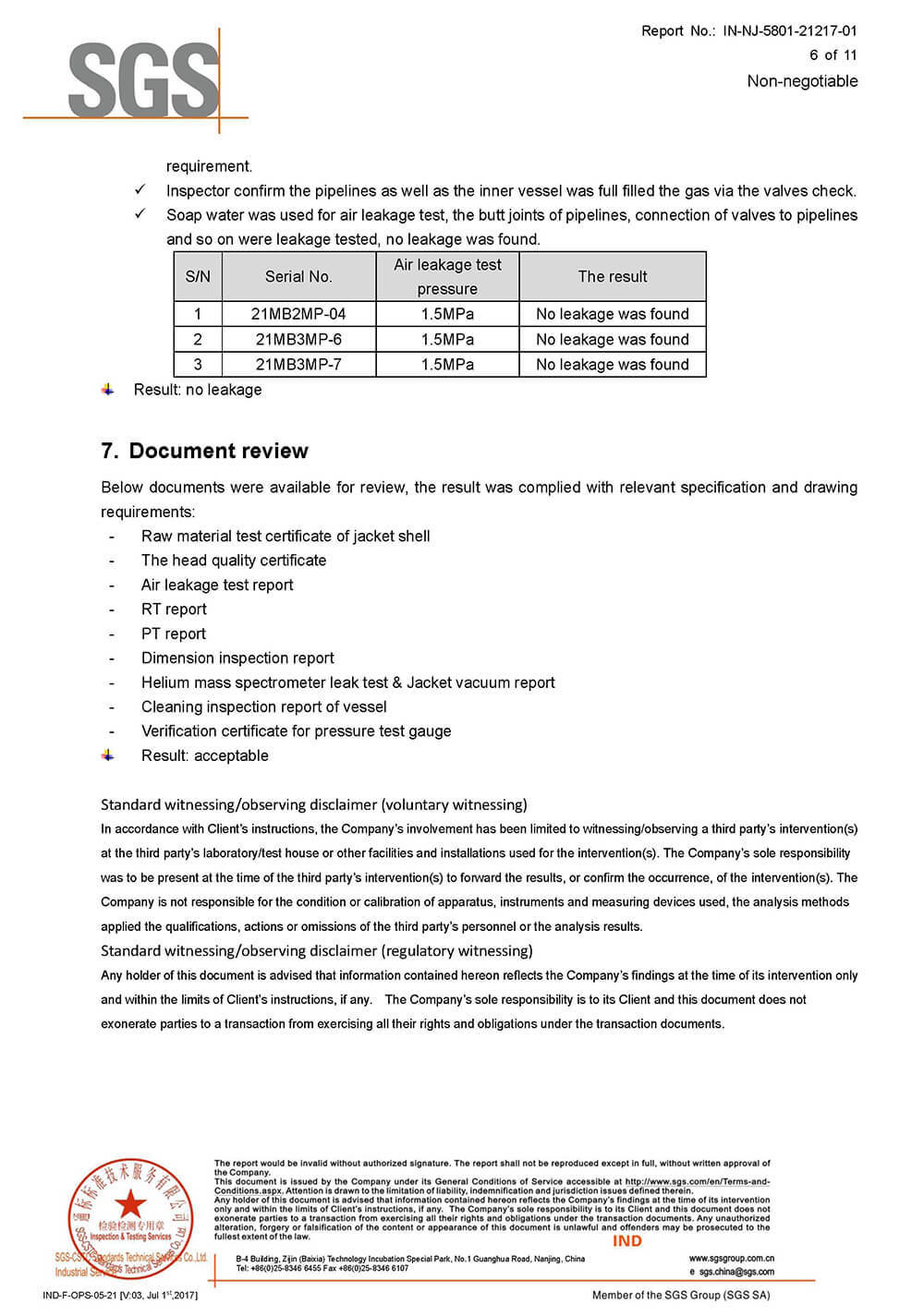

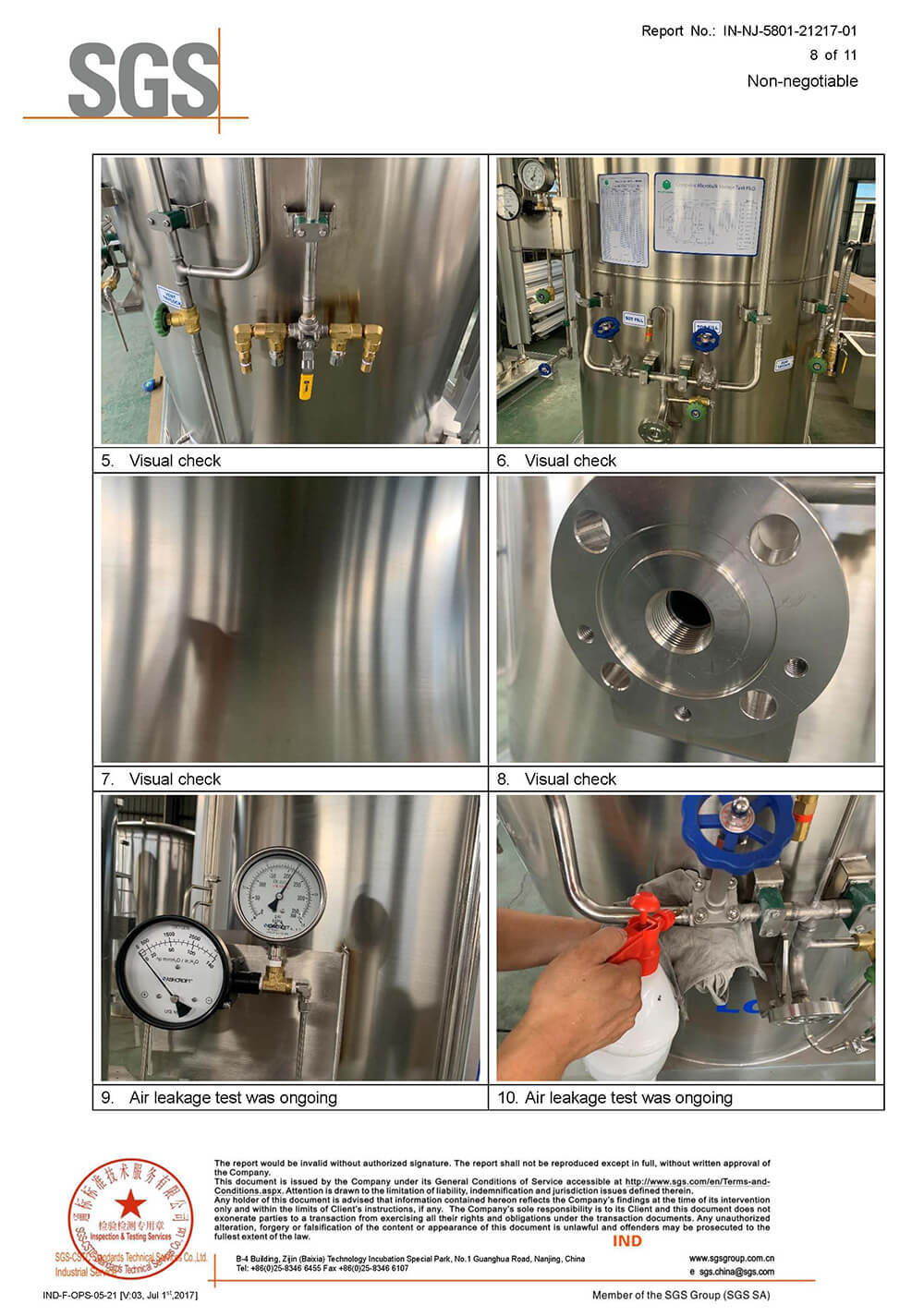

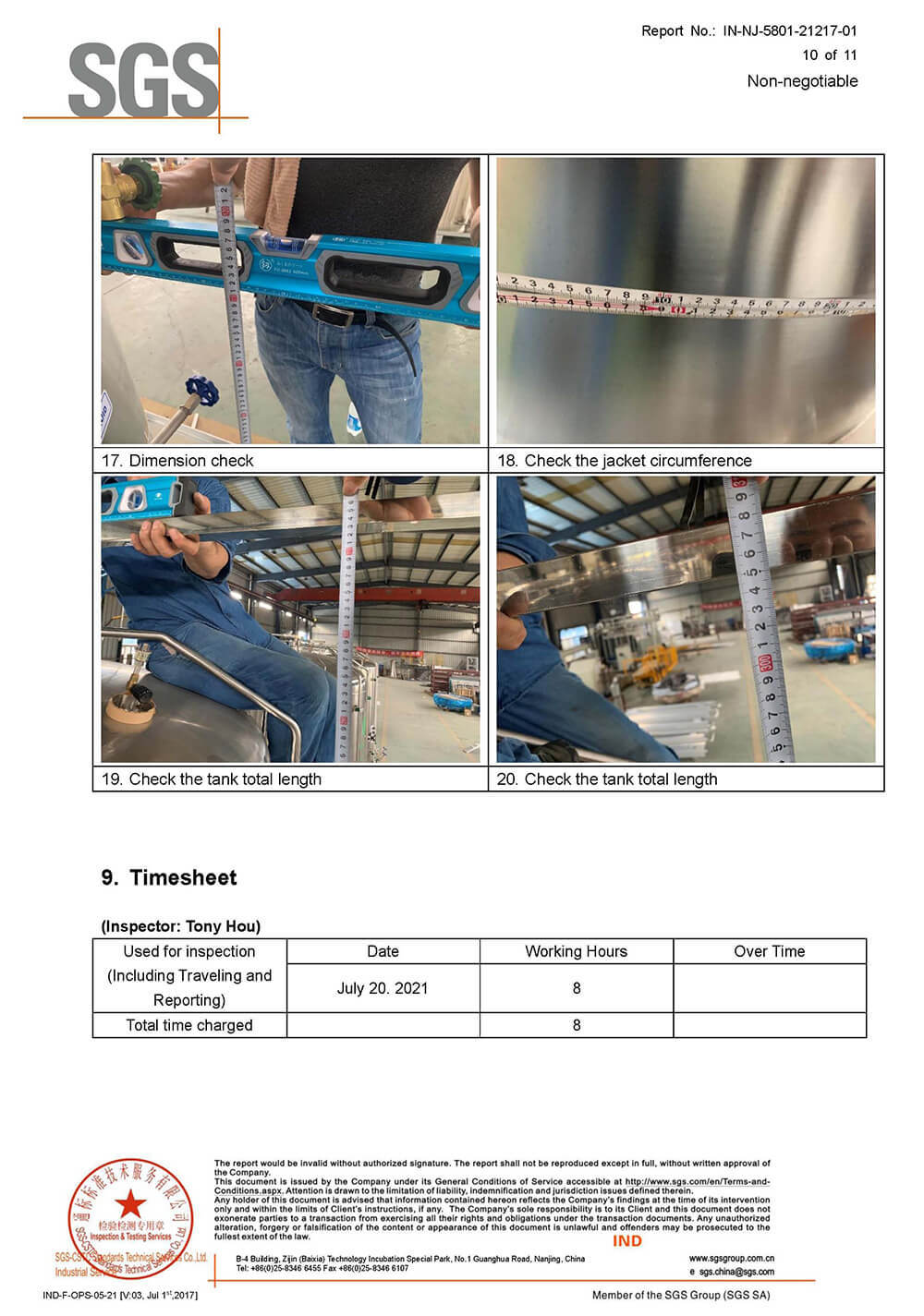

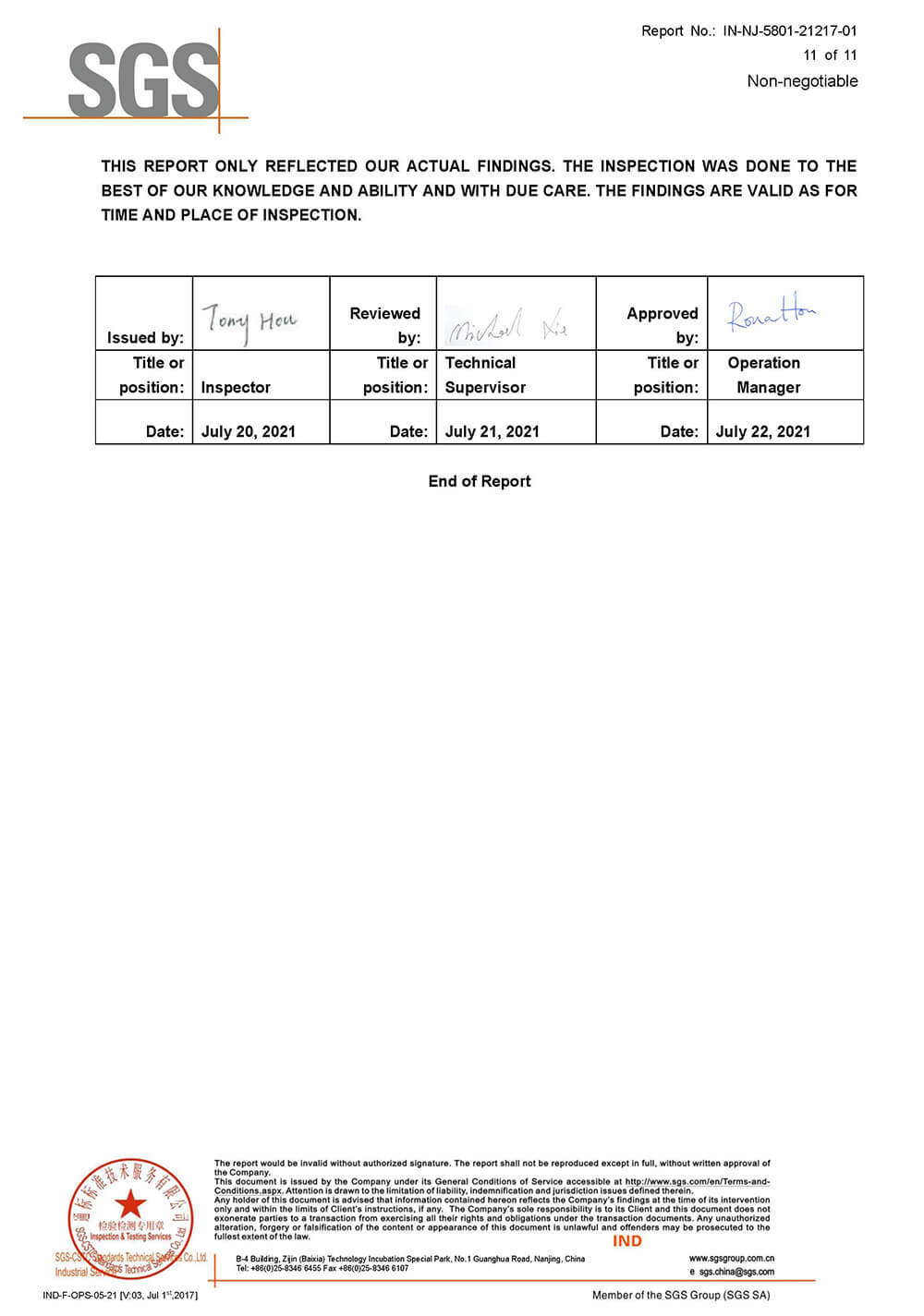

Standard Compliance: Meets ASME VIII Section 1 (cryogenic vessels) and GB/T 37247-2018 (Chinese microbulk LNG tank standard); SGS certified (inspection report includes visual checks, dimension tests, and air leakage tests).

Quality Control: Every unit undergoes helium mass spectrometer leak tests (leak rate <1×10⁻⁹ Pa·m³/s) and jacket vacuum tests; raw material certificates (for SA-240M 304) are provided for traceability.

Client-Centric Certifications: Additional certifications (e.g., CE for EU, ISO for global markets) can be arranged upon request; all documents are translated into English for international clients.

Warranty: 24-month warranty on the tank body and insulation; 12-month warranty on vaporizers, regulators, and valves; free technical support for the first year.

Reference certifications and reports:

Packaging: Shipped in 20OT or 40OT open-top containers; the unit is fixed with steel brackets and wrapped in moisture-proof film to protect against weather and vibration.

Shipping Methods: Sea freight (standard for global delivery), land freight (for neighboring countries like Mongolia), and air freight (for emergency orders).

Handling & Installation: Includes a detailed installation manual with 3D diagrams; optional on-site training for client technicians to ensure proper operation.

Customs Support: Prepares all necessary documents (commercial invoice, packing list, certificate of conformity) to avoid delays in customs clearance; works with local agents to assist with import procedures.

When dealing with large volumes of liquids and gases, choosing the right storage and transport solution is crucial. One of the most common options is the ISO tank, which is designed for safe and efficient transport. However, there’s another essential option: the storage tank. In this article, we will explore the key differences between ISO tanks and storage tanks. You’ll gain insights into their designs, functionalities, and how to choose the right one for your specific needs.

In this article, we will explore the importance of ISO standards in LNG production. You will learn how ISO certification helps enhance efficiency, safety, and sustainability across the LNG supply chain.

In this article, we will explore what LNG storage tanks are, why they are essential, and how they keep LNG in its liquid form. You’ll also learn about the different types of storage tanks and the safety features that make them reliable for large-scale operations.

IntroductionCNG cylinders are transforming the way we fuel vehicles and industries. As the world seeks cleaner energy alternatives, these cylinders play a key role in storing and transporting compressed natural gas (CNG).In this article, we will explore what CNG cylinders are, their various types, how they work, and their many benefits. You’ll also learn how these cylinders are crucial in the shift toward sustainable energy solutions.

IntroductionHave you ever wondered how compressed natural gas (CNG) powers vehicles and industries while reducing emissions? As the world shifts toward greener energy, CNG has emerged as a cleaner and more sustainable alternative to gasoline and diesel.In this article, we will explore how CNG cylinders work, their design, and safety features. You’ll also learn about the environmental and economic benefits of CNG and how it’s transforming industries.

Lorry Tanker - Application in MexicoLorry Tanker - Application of Low Temperature Tankers in JordanLorry tanker - Application of low-temperature tanker transportation in Vietnam

ISO Tank - Application of Aluminum Alloy Tank Container Transportation in AlbaniaISO Tank - Peruvian LNG Substation for Storage and Transportation Applications

Lorry Tanker Transforming Cryogenic Gas Logistics in Jordan and Vietnam What distinguishes our solution is its integrated design: a high-performance cryogenic storage tank paired with a purpose-built operation compartment. This combination eliminates the need for separate transport and filling equip

Beijing SinoCleansky will participate the NOG Energy Week 2023. During the exhibition period from July 10th to July 13th, SinoCleansky will hold the sales promotion activities at their Booth No. A01For all the coming clients and visitors, SinCleansky will give best support on the CNG and LNG equipme

Application: CNG storage and transportationSpecs: 40ft, WP250bar, 8~16 tubes;Location: Indonesia“SinoCleansky ships CNG jumbo tube containers to help our clients cope with shortage of energy. CNG jumbo tube container is the best solution for CNG virtual pipeline.”

Application: CNG transportation;Specs: 20ft, WP250bar, 12tubes;Location: South Africa"SinoCleansky CNG jumbo tube containers have been supplied to South Africa more than 10years ago, and they are still running with good performance till now"

Application: CNG storageSpecs: 40ft 9tubes skid, w.p.250barLocation: Pakistan"SinoCleansky CNG jumbo tube containers enjoy the advantages of big volume and lighter weight, ideal for CNG transport and storage!"

Application: CNG transportation, mass production ensure delivery timelySpecs: 40ft, WP250bar, 12 tubes;Location: Nigeria“SinoCleansky jumbo tube trailer for CNG transportation, design 12 tubes based on client request for maximum capacity”

Microbulk Tank is designed with skid-mounted and vaporizer built-in, high quality, efficient, reliable, lower charge loss and longer liquid gas hold time…… Microbulk Tank layout will help you to be the “Hero” in wide applications including industrial , medical, welding, laser cutting, lab, etc. It’s

Industrial gas and LNG companies across nations have unlocked new efficiency with our ISO Tank. Its standard container design integrates into diverse transport systems—road, rail, sea—adapting to global logistics needs. For cryogenic gas transport, it’s the best transport container. Inside the opera

Jumbo Tube Skid Container Transforming Gas Transport for Global Clients Our Jumbo Tube Skid Containers have become a game - changer for gas transportation across international markets. In Nigeria, a CNG company, an Iraqi hydrogen firm, and an Egyptian hydrogen energy enterprise all rely on our Jumbo

Storage Tanks Powering Gas Companies in Thailand and Brazil. In the dynamic landscape of energy storage, our storage tanks have emerged as game - changers for two prominent companies. For a leading industrial gas firm in Thailand and an LNG enterprise in Brazil, our storage tanks have become the cor

In Malaysia, a leading LNG company, has revolutionized its operations using our Microbulk Tank and ISO Tank. Leverages ISO Tanks for efficient LNG transportation to its sub - stations. These robust ISO Tanks ensure safe and reliable delivery, even over long distances. At the sub - stations, our Micr

Jumbo Tube Container Skid - Application of Pipe Bundle Gas Cylinder Containers for Transportation in MexicoJumbo Tube Trailer - Application of Tube Transportation by Trailer in EgyptJumbo Tube Container Skid - Application of Chilean Tubular Gas Cylinder Containers for TransportationJumbo Tube Skid -

Cryogenic Storage Tank Container - Application of LNG Substation Storage Tanks in BrazilCryogenic Storage Tank - Installation of the Thai Cryogenic TankCryogenic Storage Tank - LNG Storage Tank Application in VietnamISO Tank & Cryogenic Storage Tank - Thailand Low Temperature Storage Tanks & ISO Tan

Email:

Telephone:

Mobile & WhatsApp:

Address: