CNG cylinders are transforming the way we fuel vehicles and industries. As the world seeks cleaner energy alternatives, these cylinders play a key role in storing and transporting compressed natural gas (CNG).

In this article, we will explore what CNG cylinders are, their various types, how they work, and their many benefits. You’ll also learn how these cylinders are crucial in the shift toward sustainable energy solutions.

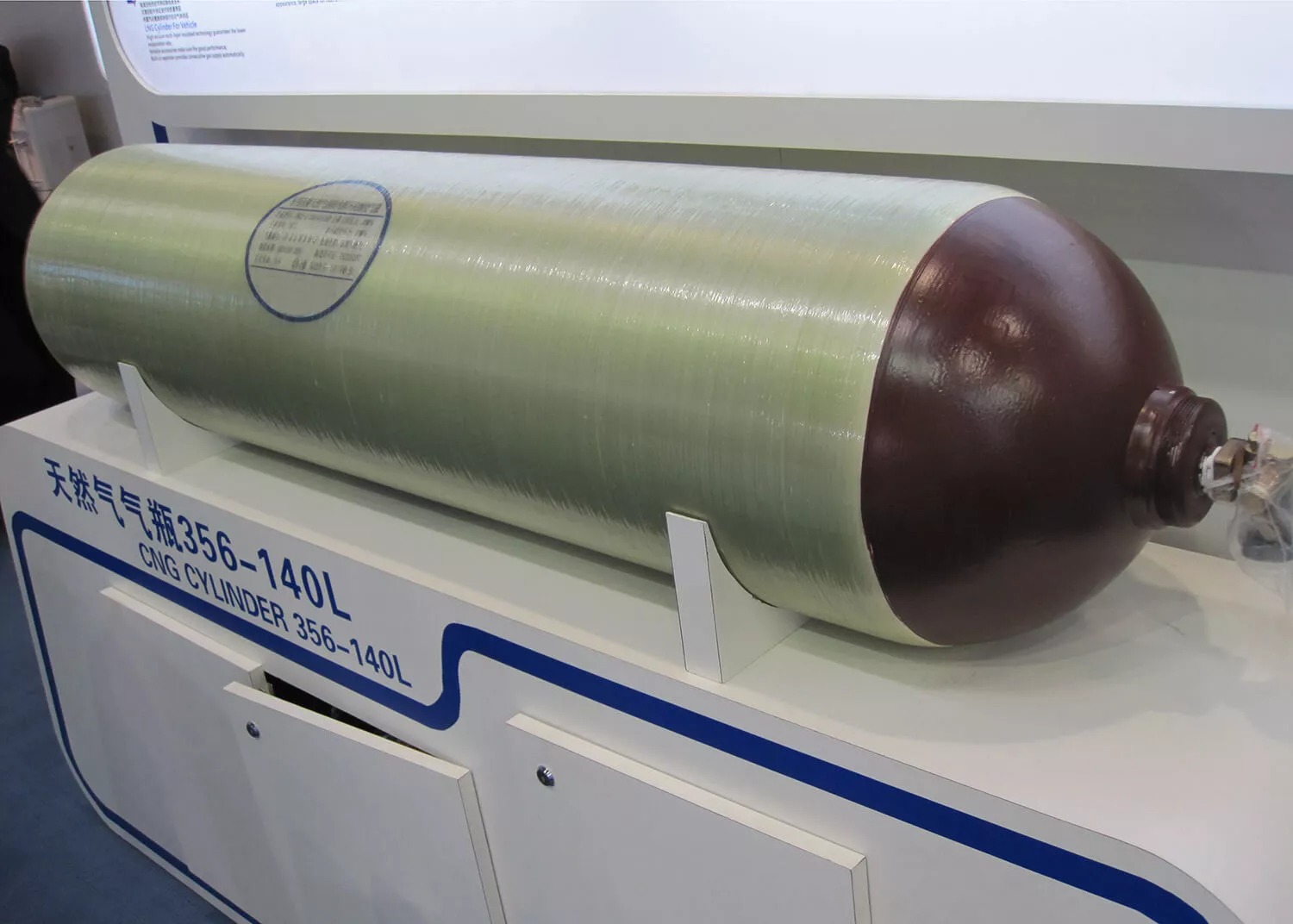

A CNG cylinder is a high-pressure storage container specifically designed to store compressed natural gas. The process of compression reduces the gas’s volume, allowing a larger amount of fuel to be stored in a smaller, more compact container. CNG cylinders are engineered to handle pressures ranging from 3000 to 3600 psi, making them essential for safely storing natural gas at high pressures. They are widely used in various sectors, including transportation, power generation, and medical industries, providing an efficient and environmentally-friendly fuel option.

CNG cylinders are built from strong, lightweight materials such as carbon fiber, fiberglass, and aluminum. These materials are chosen for their high strength-to-weight ratio, which is crucial for ensuring that the cylinders can withstand the intense pressure of stored gas without being overly heavy. In addition to their robust design, CNG cylinders are equipped with a variety of safety mechanisms to prevent leakage, rupture, or failure under pressure. Features such as pressure relief valves, overfill protection devices, and highly durable linings ensure that CNG cylinders can safely perform over their entire lifespan.

CNG cylinders are most commonly used in vehicles, such as buses, taxis, and private cars, that operate on compressed natural gas as fuel. They are also widely used in industrial applications, including power generation and gas storage for various manufacturing processes. In addition, CNG cylinders are utilized in medical fields for storing medical-grade gases that require high-pressure containment. The ability to store large quantities of fuel in a compact and portable container makes CNG cylinders a versatile solution in multiple industries.

Type I cylinders are made entirely of steel, providing a strong and durable structure that can safely hold compressed natural gas under high pressure. These cylinders are widely used in industrial applications where weight is not a major concern. However, their relatively heavier weight makes them less suitable for use in vehicles, where reducing weight is crucial to improving fuel efficiency. Despite their weight, Type I cylinders offer a cost-effective option for industries that require high-strength storage solutions.

Type II cylinders feature a metal liner, typically made from steel, that is wrapped with composite materials such as fiberglass. This two-layer design significantly improves the strength of the cylinder, enabling it to withstand the high pressures required for storing CNG while reducing overall weight. These cylinders are commonly used in vehicles and medical applications. The combination of metal and composite materials strikes a balance between strength and weight, making Type II cylinders an attractive option for both industrial and automotive use.

Type III cylinders use a thin metal liner that is fully wrapped in composite materials such as carbon fiber. The lightweight composite outer layer provides added strength, making these cylinders ideal for use in high-performance applications, such as fuel cell vehicles, aerospace, and military sectors. The reduction in weight compared to Type I cylinders is a key benefit, as it allows for better fuel efficiency and load capacity in vehicles.

Type IV cylinders are the most advanced design, incorporating a non-metallic polymer liner that is fully wrapped in carbon fiber. This design makes Type IV cylinders extremely lightweight and durable, offering superior performance for applications in vehicles and industrial systems. They are particularly advantageous in applications where weight is a critical factor. Their innovative design also provides enhanced safety features, including improved resistance to impact and corrosion. As a result, Type IV cylinders are increasingly being used in modern vehicles and high-demand industries.

Here’s a comparison of the different types of CNG cylinders:

| Cylinder Type | Material | Weight | Strength | Common Applications | Advantages |

|---|---|---|---|---|---|

| Type I: All-Metal Cylinders | Steel | Heavy | High-pressure capable | Industrial, stationary applications | Cost-effective, durable |

| Type II: Hoop-Wrapped Composite Cylinders | Steel liner, fiberglass wrap | Moderate | High-pressure capable | Vehicles, medical applications | Stronger, lighter than Type I, cost-efficient |

| Type III: Fully Wrapped Composite Cylinders with Metal Liner | Thin metal liner, carbon fiber | Lightweight | High-strength, high-performance | Fuel cell vehicles, aerospace, military | Light, strong, ideal for high-performance needs |

| Type IV: Fully Wrapped Composite Cylinders with Plastic Liner | Polymer liner, carbon fiber | Very lightweight | Ultra-high strength | Modern vehicles, high-demand industries | Extremely light, resistant to impact, corrosion |

CNG is a cleaner-burning fuel compared to gasoline and diesel. When combusted, CNG produces significantly fewer harmful emissions, such as carbon monoxide, nitrogen oxides, and particulate matter, which contribute to air pollution. The reduction in greenhouse gas emissions, particularly carbon dioxide (CO2), makes CNG a crucial part of efforts to reduce the environmental impact of transportation and energy consumption. By adopting CNG cylinders, both individuals and industries can play an active role in mitigating climate change.

The economic advantages of using CNG cylinders are significant. Compressed natural gas is generally more affordable than gasoline or diesel, which can lead to substantial cost savings over time. In particular, businesses operating fleets of vehicles can benefit from lower fuel costs and reduced maintenance expenses. The long lifespan of CNG cylinders, typically up to 20 years, adds further cost efficiency, as it minimizes the need for frequent replacements. Additionally, the widespread availability of natural gas helps stabilize its cost, providing a reliable fuel option for long-term use.

CNG cylinders are designed with a high emphasis on safety. They are built to withstand the high pressures associated with storing compressed natural gas, and they are equipped with advanced safety features to prevent accidents. The narrow flammability range and high ignition temperature of natural gas make it one of the safest gases to store in high-pressure cylinders. Furthermore, the inclusion of safety valves, overfill protection, and rigorous manufacturing standards ensure that CNG cylinders remain reliable and safe throughout their operational life.

The lightweight nature of CNG cylinders makes them ideal for use in vehicles, where weight is a critical factor. They are easy to transport, install, and maintain, which is especially beneficial for fleets and transportation companies looking to reduce costs and improve operational efficiency. The compact design of these cylinders also allows for easy integration into vehicles, further simplifying the transition to CNG as a fuel source.

CNG cylinders are filled at refueling stations where compressed natural gas is pumped into the cylinders under high pressure. The process involves specialized refueling equipment designed to safely handle the transfer of gas into the cylinder, ensuring that it reaches the desired pressure without exceeding safe limits. Once filled, the cylinders store the gas at a much higher density than in its natural state, making it an efficient storage solution for fuel.

When a vehicle powered by CNG requires fuel, a valve opens, allowing the gas to flow from the cylinder into the engine's combustion chamber. The CNG mixes with air and is ignited, providing the power needed to propel the vehicle. This controlled release of gas ensures that the engine receives a consistent supply of fuel, allowing for smooth and efficient vehicle operation.

As CNG is consumed by the engine, the pressure inside the cylinder decreases. CNG cylinders are equipped with pressure regulators that maintain the pressure within safe limits. This ensures that the gas is delivered to the engine at a steady rate, providing reliable fuel supply and optimizing the engine's performance.

To ensure that CNG cylinders remain in safe working condition, they must undergo regular safety inspections. These inspections typically include leak tests, pressure tests, and visual checks for any signs of wear or damage. Routine maintenance helps prevent accidents and ensures that cylinders continue to function optimally. Inspections should be conducted by certified professionals at regular intervals, typically every 3 to 5 years.

Maintaining CNG cylinders involves more than just periodic inspections. It also includes regular cleaning, valve checks, and ensuring that pressure relief devices are functioning properly. Proper maintenance practices, such as using appropriate handling equipment and ensuring that cylinders are stored in safe environments, are crucial for extending the lifespan and ensuring the safe operation of CNG cylinders.

CNG cylinders should always be stored in a dry, well-ventilated area, away from heat sources and chemicals. It’s important to handle the cylinders carefully to avoid damage. For example, cylinders should never be dropped or subjected to rough handling, as this could cause structural damage or compromise the safety features. Using proper lifting and handling equipment ensures that the cylinders are moved safely and securely.

CNG and liquefied natural gas (LNG) are both derived from natural gas, but CNG is easier to store and transport. Unlike LNG, which requires cryogenic temperatures for storage, CNG can be stored in high-pressure cylinders at ambient temperatures. This makes CNG a more practical and cost-effective option for everyday use, particularly in transportation.

CNG offers numerous advantages over traditional fuels such as gasoline and diesel. Not only is it more affordable, but it also produces fewer emissions, making it a more environmentally friendly option. The transition to CNG as a primary fuel source can help reduce dependence on fossil fuels, lower transportation costs, and contribute to cleaner air quality in urban areas.

Here’s a quick comparison of CNG, LNG, and traditional fuels:

| Energy Source | Storage Requirements | Fuel Efficiency | Emissions | Cost | Environmental Impact |

|---|---|---|---|---|---|

| CNG | High-pressure cylinders at ambient temp | High fuel efficiency | Low CO2, CO, NOx emissions | More affordable than gasoline and diesel | Cleaner, reduces air pollution |

| LNG | Cryogenic storage at very low temperatures | Lower fuel efficiency | High CO2 emissions in production | Higher cost due to storage and transport | Less clean than CNG, more energy-intensive |

| Gasoline/Diesel | Liquid storage at ambient temperature | Moderate fuel efficiency | High CO2, CO, NOx emissions | Expensive and volatile | Major contributor to pollution |

As demand for clean energy sources rises, the infrastructure supporting CNG is expanding rapidly. The number of CNG refueling stations is growing, particularly in urban centers and along key transportation routes. This expansion will make it easier for individuals and businesses to adopt CNG-powered vehicles, further driving the shift toward sustainable transportation.

Advances in technology are continuously improving the design and performance of CNG cylinders. New lightweight materials and smarter monitoring systems are being integrated into cylinder designs, increasing their efficiency and safety. These innovations are making CNG cylinders more adaptable and cost-effective, encouraging wider adoption in both commercial and private sectors.

Despite its benefits, CNG adoption faces challenges such as limited refueling infrastructure and higher conversion costs for vehicles. However, these challenges also present opportunities for innovation and growth. As technology improves and infrastructure expands, CNG is likely to become a more viable and widespread energy source for a variety of applications.

CNG cylinders are essential in the shift toward sustainable energy. They offer numerous benefits, such as lower emissions, cost savings, and enhanced safety. As CNG infrastructure grows and technology evolves, CNG cylinders will play a crucial role in reducing environmental impact.

Beijing SinoCleansky Technologies Corp offers high-quality CNG cylinders designed to provide safe, efficient, and cost-effective solutions for industries. Their products meet the demands of a cleaner, greener energy future, offering long-term value for businesses and individuals.

A: A CNG cylinder is a high-pressure container designed to store compressed natural gas (CNG) safely. It allows for efficient storage and transportation of CNG in various industries, especially in vehicles.

A: CNG cylinders store natural gas at high pressure, typically between 3000 to 3600 psi. When needed, the gas is released to fuel engines, providing a clean and efficient energy source.

A: CNG cylinders are cost-effective, environmentally friendly, and safe. They offer lower emissions and reduce fuel costs compared to gasoline and diesel, making them an ideal choice for clean energy.

A: CNG cylinders typically last between 15 to 20 years, thanks to their durable construction and ability to withstand high pressure over time.

A: Using CNG cylinders in vehicles offers numerous advantages, including reduced emissions, lower fuel costs, and a cleaner, more sustainable fuel option compared to traditional fuels like gasoline and diesel.

A: Yes, CNG cylinders are widely used in industrial applications, such as power generation and medical fields, where compressed natural gas is needed for various processes.

When dealing with large volumes of liquids and gases, choosing the right storage and transport solution is crucial. One of the most common options is the ISO tank, which is designed for safe and efficient transport. However, there’s another essential option: the storage tank. In this article, we will explore the key differences between ISO tanks and storage tanks. You’ll gain insights into their designs, functionalities, and how to choose the right one for your specific needs.

In this article, we will explore the importance of ISO standards in LNG production. You will learn how ISO certification helps enhance efficiency, safety, and sustainability across the LNG supply chain.

In this article, we will explore what LNG storage tanks are, why they are essential, and how they keep LNG in its liquid form. You’ll also learn about the different types of storage tanks and the safety features that make them reliable for large-scale operations.

IntroductionCNG cylinders are transforming the way we fuel vehicles and industries. As the world seeks cleaner energy alternatives, these cylinders play a key role in storing and transporting compressed natural gas (CNG).In this article, we will explore what CNG cylinders are, their various types, how they work, and their many benefits. You’ll also learn how these cylinders are crucial in the shift toward sustainable energy solutions.

IntroductionHave you ever wondered how compressed natural gas (CNG) powers vehicles and industries while reducing emissions? As the world shifts toward greener energy, CNG has emerged as a cleaner and more sustainable alternative to gasoline and diesel.In this article, we will explore how CNG cylinders work, their design, and safety features. You’ll also learn about the environmental and economic benefits of CNG and how it’s transforming industries.

Lorry Tanker - Application in MexicoLorry Tanker - Application of Low Temperature Tankers in JordanLorry tanker - Application of low-temperature tanker transportation in Vietnam

ISO Tank - Application of Aluminum Alloy Tank Container Transportation in AlbaniaISO Tank - Peruvian LNG Substation for Storage and Transportation Applications

Lorry Tanker Transforming Cryogenic Gas Logistics in Jordan and Vietnam What distinguishes our solution is its integrated design: a high-performance cryogenic storage tank paired with a purpose-built operation compartment. This combination eliminates the need for separate transport and filling equip

Beijing SinoCleansky will participate the NOG Energy Week 2023. During the exhibition period from July 10th to July 13th, SinoCleansky will hold the sales promotion activities at their Booth No. A01For all the coming clients and visitors, SinCleansky will give best support on the CNG and LNG equipme

Application: CNG storage and transportationSpecs: 40ft, WP250bar, 8~16 tubes;Location: Indonesia“SinoCleansky ships CNG jumbo tube containers to help our clients cope with shortage of energy. CNG jumbo tube container is the best solution for CNG virtual pipeline.”

Application: CNG transportation;Specs: 20ft, WP250bar, 12tubes;Location: South Africa"SinoCleansky CNG jumbo tube containers have been supplied to South Africa more than 10years ago, and they are still running with good performance till now"

Application: CNG storageSpecs: 40ft 9tubes skid, w.p.250barLocation: Pakistan"SinoCleansky CNG jumbo tube containers enjoy the advantages of big volume and lighter weight, ideal for CNG transport and storage!"

Application: CNG transportation, mass production ensure delivery timelySpecs: 40ft, WP250bar, 12 tubes;Location: Nigeria“SinoCleansky jumbo tube trailer for CNG transportation, design 12 tubes based on client request for maximum capacity”

Microbulk Tank is designed with skid-mounted and vaporizer built-in, high quality, efficient, reliable, lower charge loss and longer liquid gas hold time…… Microbulk Tank layout will help you to be the “Hero” in wide applications including industrial , medical, welding, laser cutting, lab, etc. It’s

Industrial gas and LNG companies across nations have unlocked new efficiency with our ISO Tank. Its standard container design integrates into diverse transport systems—road, rail, sea—adapting to global logistics needs. For cryogenic gas transport, it’s the best transport container. Inside the opera

Jumbo Tube Skid Container Transforming Gas Transport for Global Clients Our Jumbo Tube Skid Containers have become a game - changer for gas transportation across international markets. In Nigeria, a CNG company, an Iraqi hydrogen firm, and an Egyptian hydrogen energy enterprise all rely on our Jumbo

Storage Tanks Powering Gas Companies in Thailand and Brazil. In the dynamic landscape of energy storage, our storage tanks have emerged as game - changers for two prominent companies. For a leading industrial gas firm in Thailand and an LNG enterprise in Brazil, our storage tanks have become the cor

In Malaysia, a leading LNG company, has revolutionized its operations using our Microbulk Tank and ISO Tank. Leverages ISO Tanks for efficient LNG transportation to its sub - stations. These robust ISO Tanks ensure safe and reliable delivery, even over long distances. At the sub - stations, our Micr

Jumbo Tube Container Skid - Application of Pipe Bundle Gas Cylinder Containers for Transportation in MexicoJumbo Tube Trailer - Application of Tube Transportation by Trailer in EgyptJumbo Tube Container Skid - Application of Chilean Tubular Gas Cylinder Containers for TransportationJumbo Tube Skid -

Cryogenic Storage Tank Container - Application of LNG Substation Storage Tanks in BrazilCryogenic Storage Tank - Installation of the Thai Cryogenic TankCryogenic Storage Tank - LNG Storage Tank Application in VietnamISO Tank & Cryogenic Storage Tank - Thailand Low Temperature Storage Tanks & ISO Tan

Email:

Telephone:

Mobile & WhatsApp:

Address: